Electrifying Chemistry for cost and waste reduction:

We develop new innovative processes for the pharmaceutical and cosmetics industry

Benefits

The production of chemicals by electrosynthesis has several advantages

Reduction of production costs

Waste reduction

Easy scale-up

Substitution of toxic or corrosive chemicals

Comparison of the classical / Electrochemical approach

Classical approach

The manufacture of some chemicals still requires the use of corrosive and/or toxic reagents, non-renewable raw materials, large quantities of organic solvents, high temperatures and/or pressures.

The impact on the environment is significant: the pharmaceutical industry, although weighing 28% less in the economy than the automobile industry, is 13% more polluting (source).

Electrochemical approach

The electrochemical approach consists of using electrical energy and power to initiate chemical reactions. In this way, it is possible to improve or eliminate chemical reaction steps making your overall production more profitable and less impacting on the environment. The difficulty lies in characterizing the key parameters for optimal performance. Our team has been working on this technology for several years and has obtained the expertise needed to find the right parameters.

Comparison of the estimated environmental impact in the case of antibiotic production

%

Reduction of tons of CO2 emissions compared to conventional production

%

Reduction of tons of waste compared to conventional production

Our services

Many chemicals can be produced by électrosynthesis. In order to enable you to determine its economic potential, we offer various services:

1. Feasibility study

Lasting 3 to 7 days, it can be used to estimate the potential for improvement via the electrochemical pathway

2. Pre-pilot study

Lasting from about two weeks to two months, it allows to determine the efficiency of the electrochemical route at an average of about 20%.

3. Production

Once the previous studies have been completed, we have all the necessary equipment to manufacture several kilograms of your product.

Example of a customer wishing to produce an ingredient for the cosmetics industry :

Once the feasibility study was conclusive, Innoverda took two months to complete the pre-pilot study and estimate that the molecule would cost at least 30% less during the production phase. The client decided to continue for the production phase where Innoverda finally managed to reduce production costs by 40% with a production of 5kg/ month.

Presentation of electrosynthesis

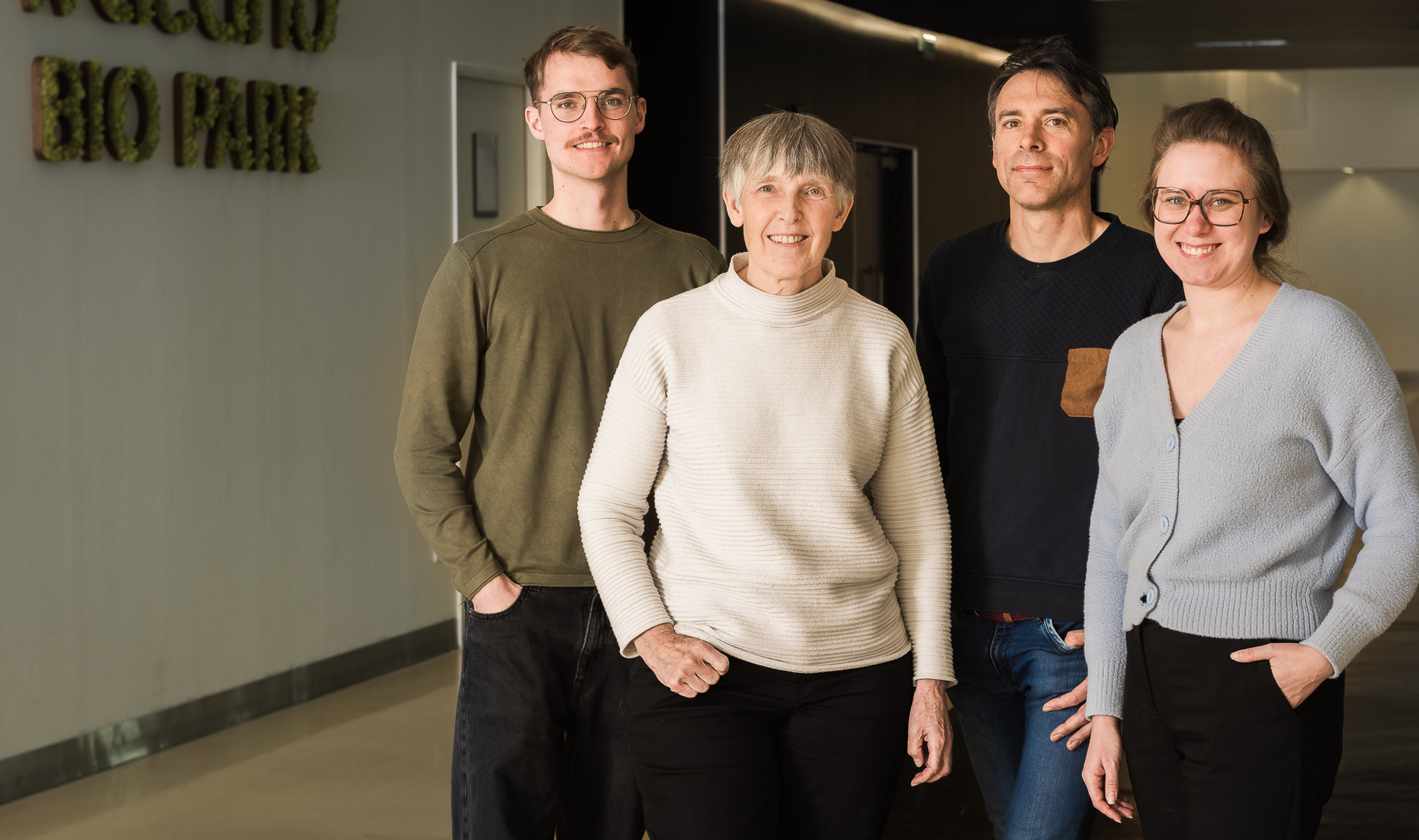

The team

Irene Erdelmeier

Founder and President

More than 15 international patents registered

Sylvain Daunay

Organic Chemistry Researcher

15 years of expertise in synthetic chemistry

Charlotte Schmitt

Organic chemistry technician

Samuele Marinari

Doctoral student in Organic Chemistry

News

Contact us

Address

Innoverda

Villejuif Bio Park

1 Mail from Professor Georges Mathé

94800 VILLEJUIF - France

irene.erdelmeier@innoverda.com